These optics allow the laser beam to be focused to a much smaller spot, producing sharper images at tighter tolerances. It's particularly suited to intricate engraving and direct marking on some metals.

HPDFO High Power Density Focusing Optics (HPDFO) uses a patented method to expand the laser beam within the focusing carriage. This expansion allows the beam to be focused into a much smaller focal spot, suitable for intricate, tight-tolerance engraving and for direct marking on some metals. In addition to sharper images and expanded material processing capability, systems using HPDFO benefit from lighter-weight delivery optics and an efficient motion system .

Universal's Patented HPDFO Accessory

Looking for a way to add even more capabilities to your Universal Laser System? Try our High Power Density Focusing Optics! High Power Density Focusing Optics, HPDFO for short, is a patented system composed of a collimator and a specially designed HPDFO lens kit. The collimator expands and "straightens" the beam as it exits the laser, and then the HPDFO lens kit focuses the laser beam onto a much more concentrated spot than can be practically achieved with standard optics systems, increasing the power density of the laser. In order to produce a similar spot size using standard optics, the focal length would need to be as short as .75" to 1", which is too short to be usable in most applications. HPDFO can increase the utility of all our current systems and a number of older models as well.

|

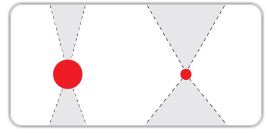

Laser Beam Spot

Size Universal's HPDFO produces a smaller, more focused beam "spot" than a standard optical laser beam delivery system. HPDFO increases the power density of the laser to achieve the effects of a laser of much higher power.

|

HPDFO was specifically designed to get the smallest spot size and highest power density possible at CO2 laser wavelengths. Due to the nature of laser beam convergence and divergence, however, it is best used for engraving very flat materials or cutting very thin materials. It's not the right choice for every job, but adding the metal-marking capability and smaller spot size of High Power Density Focusing Optics to your laser toolkit is a smart decision for almost any Universal owner.

How to use it?

|

Engrave directly on some metals

Marking on metals with standard power density optics typically requires several hundred watts of CO2 laser energy or the use of a marking compound such as Cermark or Thermark. Not so with the HPDFO! The higher power density provided by the HPDFO allows direct marking on steel, stainless steel, titanium and chrome with CO2 lasers rated at 25 watts or higher.

|

|

Make sharper cuts and more intricate engravings

Engraving and cutting tasks involving thin, closely spaced lines are much clearer when using HPDFO due to the smaller spot size. The difference between engraving with a standard lens and engraving with HPDFO is similar to the difference between cutting foam with a bread knife and cutting it with an X-Acto blade.

|

|

Create higher-definition in photographs

HPDFO really excels when engraving photographs. The smaller spot size allows you to produce sharper engravings from photographs taken at high resolutions ¯high megapixel counts ¯than standard optics.

|